Maximizing the Flow of Lean Knowledge – 21st Century Lean Management

Welcome to Episode 30 of The Impruvers Podcast, where we wrap up our four-part series on Knowledge Management.

In this episode, host Calvin L. Williams challenges us to look in the mirror and apply the principles of Operational Excellence to how we manage our own Lean and Continuous Improvement initiatives.

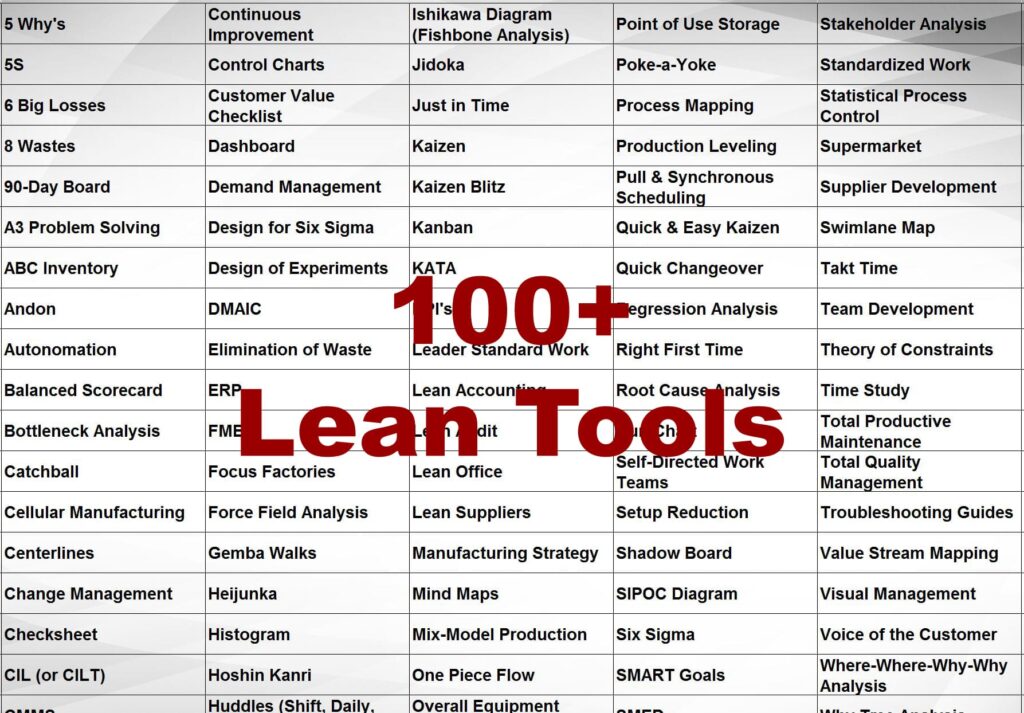

If we are to be the purveyors of excellence, we must eliminate the waste in our own processes. Calvin reviews the “8 Wastes” (DOWNTIME) specifically within the context of Lean management, identifying common pitfalls such as the “inventory” of green belt training that is forgotten immediately, or the “motion” of bureaucratic approval processes.

In this episode, you will learn:• How to spot waste in your CI program: From “overproduction” of reports nobody reads to the “transporting” of paper A3s, find out where your program is losing efficiency.•

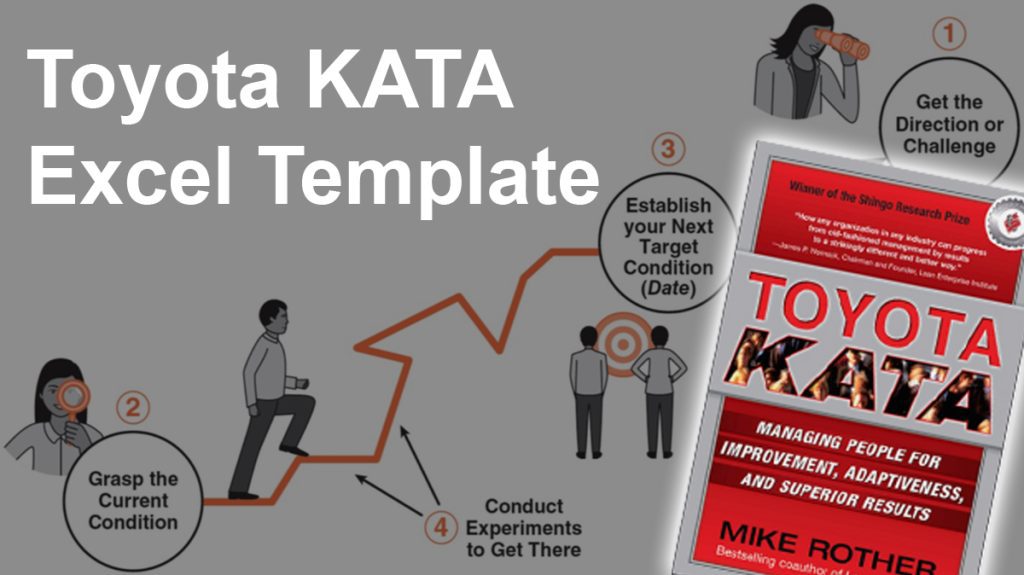

** The shift from Push to Pull:**

Why we must move away from week-long classroom training and towards “on-demand” and “just-in-time” knowledge transfer that helps people solve problems in real-time.

• The power of Digital & Automation: Why analog methods do not scale and how automating administrative tasks allows machines to do the heavy lifting so you can focus on higher-impact activities.

• Securing your seat at the table: How removing the friction of manual knowledge management frees you up to build relationships with decision-makers and influence strategy before bad decisions are made.

The goal isn’t just more intelligence; it is less delay, less knowledge inventory, and more value delivered to the customer. It is time to stop administering Lean and start influencing the organization.

Sponsor: This episode is brought to you by Impruver—providing the tools, tech, team, and training to empower the continuous improvement community. Visit impruver.com or Impruver University to learn more.

Let’s get better every day!

Responses